We now offer a consultancy in Vehicle Design.

We have actually been doing this for years already, and decided to give the business a name!

John Brett has been practicing as a LVV Certifier for 12 years, and been designing, building and modifying vehicles of all sorts for over 40 years.

His experience is as a qualified professional, with extensive experience and training in Metallurgy, Welding, Stress analysis, Vehicle manufacture, and Mechanical Design.

Here are some of the things we are currently doing- Design and Certify

Design, stress analysis, detail working drawings for new construction and modifications to:

1 Ladder frame chassis

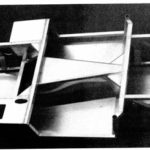

2 Space-frame chassis

3 Monocoque body shells

Examples include:

1 Boat trailers

2 Chassis stretches, C-Notches, complete chassis replacements

2 Stretch Limousines

3 Utility and Convertible conversion

John’s experience ranges from bicycles frames to penstock transporters, and includes pioneering design of ready-mix concrete trucks.

See Body Restructure: Body Restructure

Suspension and Steering Design

Geometry analysis and component design.

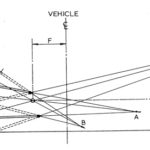

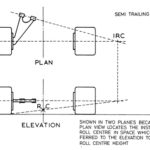

1 Graphical analysis of Camber and Caster, Roll Centre, etc

2 Graphical analysis of bump-steer, on front and rear axles

3 Detailed component working drawings

4 Metallurgical and welding recommendations for modified parts.

John’s experience started with technical training, followed by setting up cars for racing at the Levin race circuit in the 1960’s

Power train Design and Modification

Technical advice, and practical strategies for power-train design and re-power.

The expertise available runs from Human powered, through Electric powered, through to Gas Turbine power of over 100 Mw, and includes all sorts of piston powered and hybrid options in between.

John manufactured millions of dollars worth of Turbine components in NZ, including Curtiss Wright Power Turbine stator casings, to keep Electricorp Power Stations operating

Electric Vehicles

We have Certified and assisted with the design of many electric vehicles. This follows on from my extensive experience in the Electric Power Industry, and as Generation Engineer Gas Turbines at the old Electicorp

Electic Rav 4, featured in SHED magazine

Braking Systems

Many brake upgrades are easy, bolt on changes. There can be dangerous problems however if components do not match, or are set up incorrectly.

Problems arise with master cylinder and boosters sizes , also with proportioning valves, ABS and Electronic Brake Force distribution systems.

We have dealt with all of these issues, and know the best ways to get it right.

Seating, Seatbelts, and Occupant retention

Design of stressed and unstressed seats, seatbelt installations, and anchorages.

1 Design of seatbelt geometry to meet ADR standards and to LVV Std. 175.00

2 Design of seats to ADR standards and LVV Std 185-00

3 Design of REAR-FACING seat installations to ADR standards and to LVV Standard 185-00

See my design for Unit Seats

Door and Door-retention systems

Design of “Lambo-door” hinge systems, “Suicide Door” systems, and electric openers

1 Many kits are available which are unsafe, and need major modification to meet standards.

2 Body side-structures frequently need major strengthening in many cases.

Cargo Tie-downs and Load Retention

Design of loading racks for interior fit-outs, or external racks.

1 External Glass racks

2 Internal load carrying racks and shelving

3 Tool-racks and trays for service vehicles.

Loading Equipment

Loading equipment for Vehicle recovery, Agricultural Contractors etc.

1 Special Ramp-decks for trucks

2 Ramps for loading to conventional decks

3 Self-loading trailers

Motorcycles, Trikes

We can advise and assist with Motorcycles, Choppers, Trikes, Side-cars, Motorcycle trailers, whether powered by internal combustion or electric.

Cranes, Hoists, Inspection systems

We have designed entire car assembly factories- we can offer a design service for your facilities

Contact John Brett on 0800 LOWVOLUME (0800 569865) or

Email John at john@lowvolumevehicle.co.nz

Most recent comments